Window Trimmers

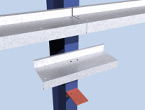

When windows are called for in side and gable cladding, Hi-Span C-Channels provide an ideal solution for window headers, sills and trimmers. Standard strut braces and diagonal ties form the load bearing system (above and below the window opening where necessary) and the use of special packing plates with countersunk holes at the strut / rail connections, and M12 countersunk fixing bolts, provides a flush finish and a clear dimension between rails.

Fixing cleats for vertical trimmers using our range of TC cleats, are countersunk similarly to also maintain a clear opening width.

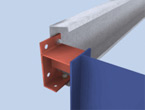

Counter Formed Plate Detail

In order to avoid countersunk cleats to strut members above windows, CFP plates can be used. These plates have large oversized 32mm diameter holes which accomodate a standard 18mm diameter counterformed hole in the channel section. The bolt thread continues through the plate to the strut cleat, where it is fixed.

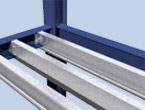

Cill Head Plate Detail

In situations where a window head / sill continues past the column face a standard channel sleeve cannot be used as the fixings will protrude into the clear opening. Continuity is still required across the face of the column, in order to distribute moments about the joints. This is achieved by introducing a hot rolled 'A' x 8mm FLT x 'B' long.

The hot rolled plate can achieve the same moment capacity as the cold rolled C-Channel assuring no failure will occur. It requires 8no 18 dia countersunk holes to continue the flush finish across the head / sill of the window. The detail shown is a recommended solution to overcome this particular situation; the dimensions are to suit standard punching holes. Final details and fabrication are not the responsibility of Hi-Span.

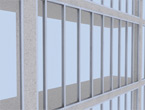

Window Channel Pressings

For window jambs and headers the Hi-Span WCP section is an ideal member. If rail centres exceed the height of the window, a WCP can be used to form a header or sill.