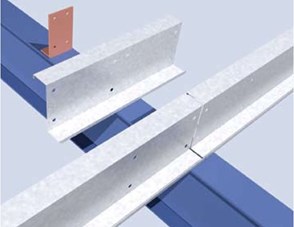

Sleeved Purlins

| The Sleeved Purlin System is easily the most popular of the three zed purlin systems available from Hi-Span. Purlins achieve a high degree of continuity over the supports by employing connecting sleeves over joints. This means that design bending moments are distributed evenly along the building length, resulting in smaller section sizes and valuable economies achieved. In the various possible arrangements of single and double span purlins, the Hi-Span sleeved system offers the customer low material costs, practical on-site advantages during erection, and excellent building performance thereafter. |

|

|

|

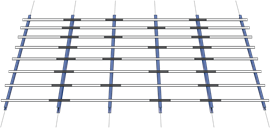

Double Span Joint Arrangement. This system combines single and double span purlins with their joints staggered and sleeved. The provision of a sleeve at the unjointed connections over the penultimate support is required. |

Single Span Joint Arrangement. Apart from the penultimate support this system has sleeves at alternate positions. Purlins must be continuous over a minimum of two spans using a sleeve, in order to create an end bay situation. (Sleeve arrangement as above, using single span purlins).