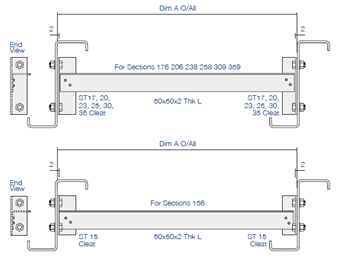

Anti-Sag Systems

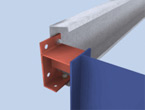

Tubular Sag Bars

Sag bars are used to restrain the bottom flange of a purlin in order to reduce its effective length when exposed to uplift conditions. Where download is critical, with a relatively small uplift the sag bars contribute very little to the structural integrity of the roof. In these situations it is possible to design the section without sag bars. When doing this, care should be taken during the erection of the cladding panels as the purlins are untied between supports, temporary bracing may then be necessary. This  addition is left to the cladders discretion.

addition is left to the cladders discretion.

|

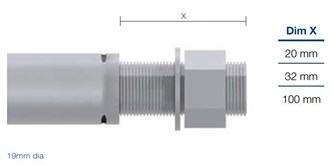

Threaded Sag Bars These 19mm diameter flow-coat galvanised and lacuered seamless tubular sag bars are preferred by many consultants and structural engineers: not only for visual effect, but also from the structural point of view. For use with zed purlins up to and including 250mm deep and on roof pitches of up to 25o. They are sturdy (0.9mm thick) and the zinc plated 2mm dia. threaded end spigots with nut and washer provide a positive fixing. (They are available in three standard lengths 20mm, 32mm, and 100mm). |

|

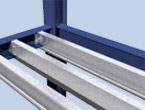

Rigid Fix Struts It is mandatory to employ the rigid fix strut in place of tubular sag bars in a variety of situations. - Roof pitches less than 5 degrees |

|

|

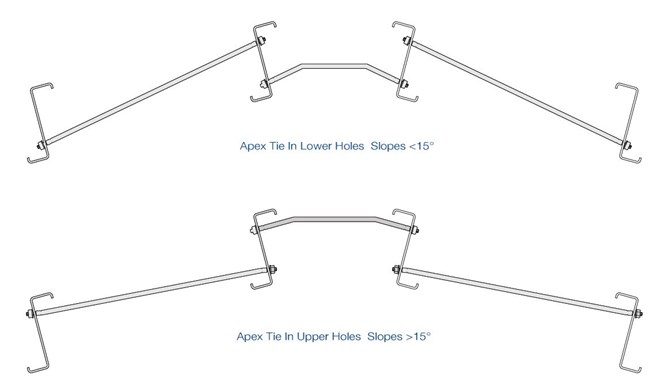

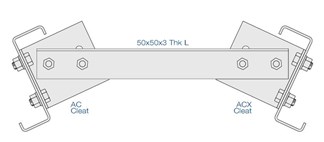

Rigid Apex Tie The rigid apex tie is made from a thicker angle than the struts for added strength. AC cleats are used either end allowing for roof pitches up to 30o. For steeper roof slopes please contact our Technical Department

|

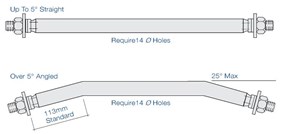

Tubular Apex Tie These are made from the same material as our threaded sag bars and are manufactured to suit the configuration of the ridge purlins. Please note that the minimum distance to a bend is 113mm, and that the maximum angle of bend is 25o

|

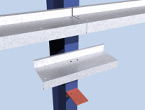

Sag Bar Configuration