Mezzanine Floor Systems

|

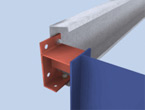

Hi-Span C-Channels are a comprehensive range of channels for a diversity of applications. Primarily for use within mezzanine floors, C-Channel sections can also be applied in many other circumstances such as door framing, roof trimming, window trimming, brickwork restraints, parapet rails and side rails. The mezzanine floor beam depths of 127, 220, 270, and 290mm are all catered for within the range, together with channel depths of 150, 170, 205, 230, 255, 305 and 350mm, which are fully compatible with our 'Z' purlin and rail sections. While mezzanine floor beams are normally punched with 18 diameter holes as standard, 14 diameter holes are also available in these sections, together with the option of counterformed holes. |

|

Single Span Design |

Double Span Design |

|

|

|

|

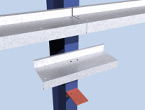

Restraint Requirements As the bottom flange of the C-Channel is usually unrestrained we recommend that a Hi-Span tubular sag rod is fitted. Where possible the channel should face toe to toe with the restraint situated in the lower gauge line holes. (Typically spans less than 3.50m do not require restraints). |

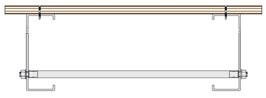

Threaded Sag Bars

These 19mm diameter flow-coat galvanised and lacquered seamless tubular sag bars are prefered by many consultants and structural engineers; not only for visual effect, but also from a structural point of view. They are sturdy (0.9mm thick) and the zinc plated 12mm dia. threaded end spigots with nut and washer provide a positive fixing. (They are available in three standard lengths 20mm, 32mm and 100mm).

Floor Cleats

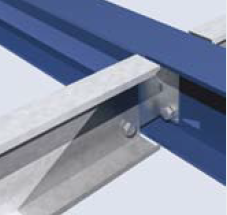

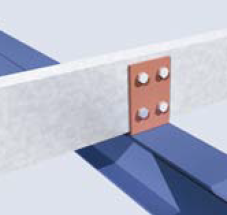

When Hi-Span C-Channels are used as mezzanine floor beams the MFB cleats should be used at the supports. The cleats are manufactured from a thicker material than the trimmer cleats to support the higher shear loads associated with floors. When a double span system is used, hot rolled cleats are needed in order to support the web of the channel. Fixing directly through the bottom flange of the channel to the supporting member is not recommended.