Anti-Sag Systems

These are necessary to ensure that the rails line level along the length of the building and also provide torsional restraint to the unrestrained flange.

The system consists of a continuous line of struts at either mid, third or quarter points along the rail span. In order to support the rails against vertical deflection diagonal tie wires are required. Where a hot rolled structural members of adequate strength is used as an eaves beam, the anti-sag system can be suspended from it therefore removing the necessity of the wires.

Additional Diagonals

Further sets of diagonal wires are required at the following dimensions. Dim H = 10m for metal cladding and 7.5m for fibre cement cladding.

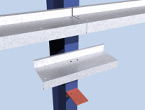

Rigid Fix Struts

Rigid-fix struts are manufactured from 2.0mm pre-galvanised material, which is riveted eiter end to ST cleats. The angle member has the capacity to resist compressive forces that may occur.

Anti-Sag Requirements

Restraints should be provided to suit the various span and sheeting conditions shown in the table below. For other forms of cladding please consult our Technical Department.

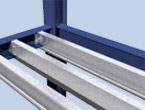

Diagonal Bracing

Diagonal braces are manufactured from seven seperate strands of wire rope with an adjustable threaded end, and a fixed 'ball type' end swaged to the wires. For all rail systems diagonal braces are required to support the rails against sagging under their own self-weight about the minor axis. Where struts can be fixed back to an adequate hot rolled eaves member, the diagonal braces are not required.

With a strut anti-sag sytsem the diagonals can be placed anywhere in the bay, but we recommend between the bottom lines as this will aid erection.

Additional sets of diagonal braces are needed according to the meterage of cladding they must support. As a rule each set can support up to 10m of metal cladding or 7.5m of fibre cement sheeting. After this further braces are required. (As an alternative to the wire rope brace system, we can also offer a tubular diagonal brace system).

The bracing bracket fixed to the cleat attached to the column must use the holes closest to the column, whereas the bracket that fixes to the centre of the rail should fix to the outer holes closest to the cladding.

|

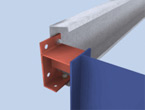

Bracing Bracket |

Rigid Bracing Bracket Where there are excessive down slope loads due to high dead loads and steep pitches, 8mm thick material is used. Also where the diagonal angles exceed or are less than the specified max/min slope, rigid bracing brackets should be used. |